The SABRE Difference

SABRE Maximum Strength Formula

Learn about our quality assurance process that delivers industry-leading products.

Our Quality Assurance Process

At SABRE, we strive to produce the most effective pepper sprays and personal safety products that will help protect you in the moments you really need them. Developing our industry-leading products, technologies and formulations like SABRE Red and SABRE Crossfire starts with extensive testing and quality control.

Quality Control: The Best from Start to Finish

From the time the red peppers get to our factory in the form of concentrate, to the time they enter your hand in our award-winning packaging - they're put to the test!

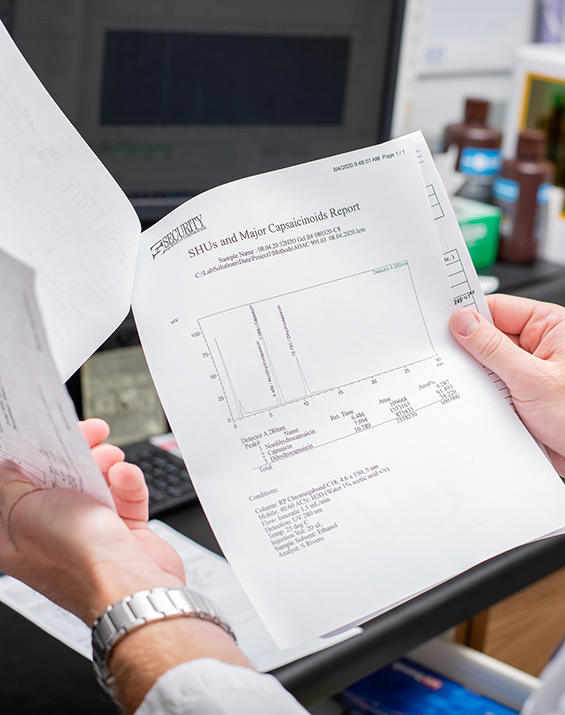

Each batch of pepper spray and pepper gel is tested in our exclusive High Performance Liquid Chromatography Laboratory - nothing leaves our factory unless it meets our high standards!

Once the formulas are mixed, each unit takes a bath - literally! The water baths ensure our products are sealed tightly to prevent leakage.

But we're also concerned with making sure our products, while extremely effective, are compatible with the law and government regulations. SABRE is ISO 9001:2015 Certified, the American EPA, and Health Canada to ensure our bear and dog sprays provide you protection in a humane way.

When it comes to personal protection for law enforcement officials, working adults, students, or outdoors travelers, the choice is clear – choose SABRE for proven results. We take pride in producing only the best for our customers.

HPLC GUARANTEE FOR QUALITY ASSURANCE

HPLC technology is the industry's #1 advantage—and it's exclusive to SABRE.

According to an independent study conducted by the University of Utah, variability rates in the concentration of active ingredients in pepper sprays have been shown to be only 70% effective, meaning that all pepper spray brands have a 30% failure rate. As the climate changes, so does the strength of red peppers and with that the effectiveness of pepper spray. With an industry-exclusive HPLC laboratory, only SABRE guarantees its maximum strength formulation in every canister to help give peace of mind, certainty, reliability, and safety when you need it most.

What does 'HPLC' mean?

HPLC stands for high performance liquid chromatography. This technology is the only way to ensure there are no pepper spray failures due to heat inconsistency. The process eliminates the possibility of bad batches and guarantees the maximum strength of SABRE pepper spray.

We are proud to provide the most consistent level of pungency possible to further increase our users’ safety.